Live and Learn

by Bud Walker

Issue No. 263 - March 1995

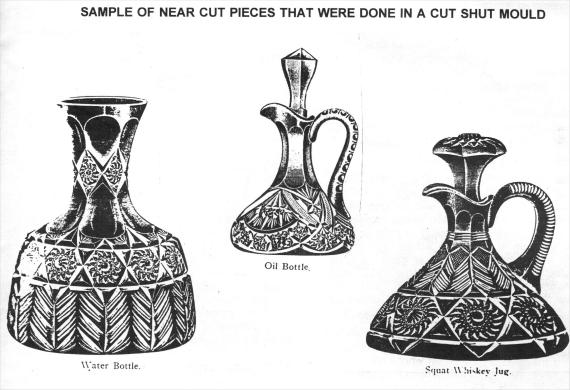

Several years ago at one of our glass club meetings, one of our members showed a small jug he had purchased. There was no doubt that it was a Cambridge jug, from the Nearcut Era. Upon closer examination we discovered the works "Near Cut" on the inside of the little jug. This made all of us wonder how the Cambridge Glass Company was able to get the words "Near Cut", which was their trademark, on the inside of the jug.

Knowing that I had some experience, having worked as a mould boy in a little backyard glass factory, I was expected to come up with the answer as to how this was done. Most of my experience in glass making was with primitive wood moulds. As for pressed pieces, I had helped in making a few bowls and cup plates. Everyone that I asked was at loss as to how the "Near Cut" got on the inside of the little jug. I was sure that the piece had been pressed in a mould. The question was how? The handle of the jug was pressed, not stuck on as it would be on a blown piece. The thing that had me totally confused was the little jug appeared to have a pontil mark on the bottom. This would indicate that the piece had been blown in a mould.

I had about given up hope of ever finding out how the little jug was

made. My interest was renewed when I read a new book on Carnival glass.

The author alluded to the fact that the Cambridge Buzz Saw Cruet had a

pontil mark which indicated the cruet was blown in a mould. The cruet

shown was much like the little jug. It was definitely a pressed piece,

you could tell by the pressed handle. I still had no clue as to how

these pieces were made. There was no way a plunger could enter through

the narrow opening at the top.

I had about given up hope of ever finding out how the little jug was

made. My interest was renewed when I read a new book on Carnival glass.

The author alluded to the fact that the Cambridge Buzz Saw Cruet had a

pontil mark which indicated the cruet was blown in a mould. The cruet

shown was much like the little jug. It was definitely a pressed piece,

you could tell by the pressed handle. I still had no clue as to how

these pieces were made. There was no way a plunger could enter through

the narrow opening at the top.

When I was told how Cambridge made these pieces, my first thought was "Bud, how dumb can you be?". After thinking about it for a while I realized that if it hadn't been for my friend Willard Kolb, I probably would have never known how these pieces were made. When I first brought up the subject to Willard, he asked if I had ever heard of a "cut shut" mould. I had to admit that I hadn't. Willard went on to explain how these pieces were made. They were made upside down. In other words the plunger entered from what would later be the bottom of the piece being made. The words "Near Cut" were on the plunger, this was how they got inside the little jug. After the piece was pressed the finisher would cut the bottom of the piece closed. Thus the name "cut shut mould". The cutting that was done to close the bottom of the piece, left the mark that looks like a pontil mark.

Fellow collectors, if you have a jug or cruet that looks like it's pressed, but has a pontil-like mark on the bottom, look at the handle. If it's pressed you probably have a piece that was made in a "cut shut mould".